Africa

Europe

Search

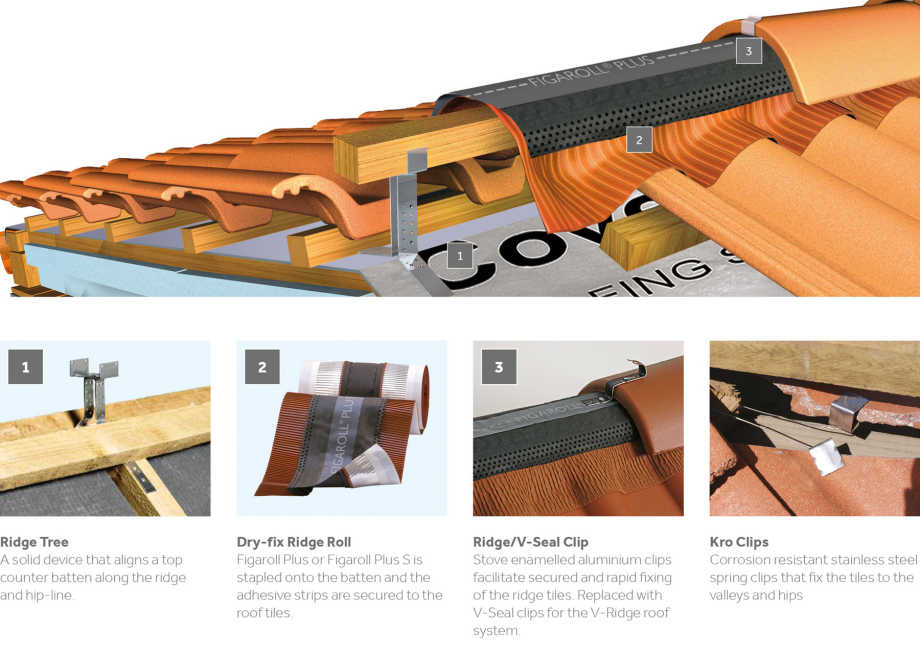

Dry Ridge System

Our innovative Dry Ridge System is a ventilating dry-fix solution for mechanically fixing ridge tiles. The system is a modern alternative to a mortar bedded ridge and creates a discreet finish that is far superior in aesthetics and function. So much so that it is the chosen ridge and hip solution by Central Developments.

THE SYSTEM MECHANICS

Installation requires a top batten on the ridge line to securely fix the ridge roll and ridge tiles.

Seals ridge to ridge to give a tried and tested weather-tight seal.

Provides an exceptionally durable method of securing ridge and hip tiles that ensures high resistance to storm damage.

Gives a continuous weather-tight ventilation path from the interior roof cavity to the outside.

| Criteria | Dry Ridge System | Mortar Bedding |

|---|---|---|

| Ventilation | Double ventilation channels allow air to escape through the ridge preventing mould and rot of roof structure | Mortar hardens and does not allow airflow through the ridge line |

| Maintenance-free | Allows expansion and contraction of roof in varying weather conditions | Hardened mortar cracks with the movement of the roof which requires ongoing maintenance and waterproofing |

| Waterproof | Water resistant and do not allow water to penetrate through the roofs surface | Water penetrates through the cracks in the mortar causing damage to the roof interior |

| Time & labour-saving | Easy to use the no-fuss, no-mess application takes approximately 2.5 hours/10m roof ridge | Takes approximately 6 hours/10m ridge line |

| Cost-saving | No long-term maintenance required | Waterproofing to seal cracks every other year |

| Design aesthetics | Neat and clean roof lines | Messy ridge and hip-lines and waterproofing overcoats. Usually the overcoat colour does not match the tile colour |

Setting standards with our product testing methods we expose our products to sunlight simulation and UV radiation, acid rain, freeze thaw resistance and thermal shock testing. We test the ease of fixing and use of our products internally. BMI weathering stations in eight countries worldwide additionally help us to simulate and predict the durability of our products many years into the future in all types of climate conditions.

Traditional mortar bedding is widely used to fix roof ridge and hip lines in South Africa. Though the initial setup costs of mortar application may be the driving factor for its popularity, its short life-span, particularly in harsh weather conditions, urges more awareness to more sustainable ridge and hip-line applications.